3D Machine Vision: Paving the Way for Smart Factories

As manufacturers race toward greater automation and digital transformation, one technology stands out for its power to bridge the physical and digital worlds: 3D machine vision. Unlike traditional imaging systems, 3D machine vision captures depth, shape, and volume—enabling real-time decisions that fuel the next generation of smart factories.

By adding dimension to how machines “see,” this cutting-edge technology is revolutionizing production floors, from quality control to robotic guidance.

What Is 3D Machine Vision?

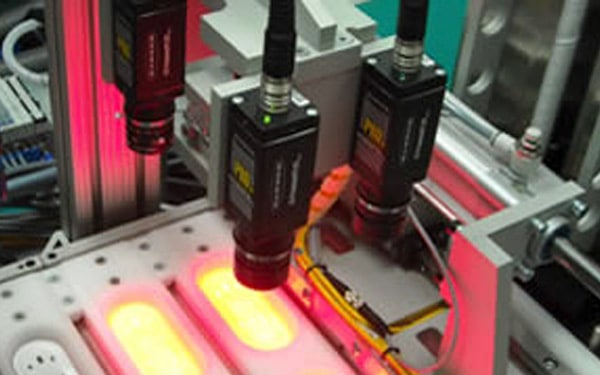

3D machine vision systems use lasers, structured light, stereo cameras, or time-of-flight sensors to generate three-dimensional representations of objects and environments. These systems go beyond surface-level scanning—they measure depth and spatial positioning with extreme precision.

That added layer of insight enables machines to adapt on the fly, recognize variations, and make decisions that previously required human judgment. In short, it’s a key enabler of flexible, autonomous manufacturing.

Applications Driving Smart Factory Performance

3D vision is already transforming core manufacturing processes across a range of industries. Here are some of the most impactful applications:

Automated Quality Control

With 3D vision, manufacturers can inspect parts and assemblies in greater detail than ever before. Systems can detect surface defects, dimensional deviations, or missing components in real-time—minimizing scrap, reducing rework, and improving product consistency.

Robot Guidance

3D machine vision allows robots to “see” their environment in three dimensions. This is critical for bin picking, part localization, and adaptive path planning. Robots equipped with 3D vision can adjust to variable positions, handle complex tasks, and work more safely alongside humans.

Assembly Verification

In high-mix, low-volume environments, verifying that each product is assembled correctly can be time-consuming and error-prone. 3D imaging automates this process, comparing real-world assemblies against CAD models or reference scans with high accuracy.

These capabilities not only enhance quality but also support regulatory compliance, especially in sectors like medical device manufacturing, aerospace, and automotive.

Benefits of 3D Machine Vision in Manufacturing

Integrating 3D vision systems into your operation unlocks several long-term advantages:

- Increased production accuracy and throughput

- Reduced labor costs and human error

- Better adaptability to product variation

- Faster changeovers and flexible automation

- Real-time decision-making that shortens response time

In short, this technology doesn’t just optimize isolated tasks—it helps future-proof your entire manufacturing workflow.

Ready for Smart Manufacturing? EAM Can Help

At Engineering Automation of Maine (EAM), we specialize in engineering and integrating advanced machine vision systems, including 3D imaging technologies that power smarter, more adaptive production environments. Whether you’re upgrading quality control, improving robotic systems, or building toward a fully connected factory, our team brings deep expertise to help you succeed.

Want to explore how 3D machine vision can transform your operation? Contact EAM today to learn how we can design a custom solution that puts your factory on the path to Industry 4.0.