Over the last several decades, machine vision systems have rapidly evolved to the extent that their application has not only become common in many manufacturing environments around the world but is vital to the success of those companies that have adopted the technology. Machine vision systems are integral to smart manufacturing initiatives, industrial operations, and overall logistics.

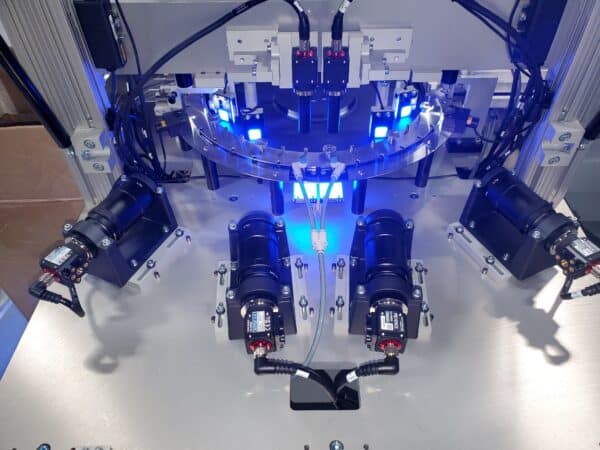

Companies that have placed a priority on optimizing manufacturing automation in their facilities benefit significantly from machine vision technology. Comprised of a robotic guidance system, machine vision uses camera-like sensors that act as eyes to monitor components, parts, or objects in conveyance for inspection and analysis on production lines or other manufacturing activities. During typical production line activities, machine vision sensors capture and process images of product parts for visual inspection. The sensors are programmed to inspect the component for accuracy, position, shape, size, colors, and even barcodes to ensure the item is processed correctly.

Benefits of Machine Vision Inspection and Analysis

Companies that invest in machine vision systems will realize improvements in production activities, see reductions in unscheduled downtime, lowering production costs, and a waste reduction. Integrating machine vision technology into production achieves higher productivity and better quality control. Traditional methods of quality control that rely on random sample testing of products are all but eliminated —the visual inspection and analysis of parts and components in real-time allows companies to conduct a 100% inspection of parts and components all the time. This means that any flaws are revealed in real-time, reducing waste and removing the possibility of shipping defective parts.

Another key to improving quality and efficiency is eliminating costs associated with human error. Nothing is quite as mind-numbing as employing labor in dedicated, repetitive tasks along a production line in a manufacturing environment. It’s not simply costly regarding efficiency and output but affects product quality. Machine vision technology can process thousands of parts per minute with speed and accuracy far exceeding human capacity. Thus, investing in machine vision technology optimizes manufacturing automation that improves productivity and quality by increasing the speed and efficiency of production lines. Inspection and analysis by a vision system are accurate and not prone to fatigue and eye strain.

Smart Factory Initiatives

A smart factory is an automated, interconnected cyber-physical system in which machine vision technology plays a vital role in the basic structure of any smart factory initiative—data acquisition, data analysis, and intelligent factory automation. Machine vision systems visually capture the physical environment and transform it into digital data that processes and analyzes production data in real time. Information can be used to track parts, increase inventory control and management, and even ensure compliance, further allowing companies to improve operational efficiency in a continuous improvement cycle.

Today, machine vision systems continue to expand and move forward, providing technology that helps manufacturers organize and manage production with increased efficiency. Investment in machine vision technology has boosted labor productivity and manufacturing output for various industries ranging from pharmaceuticals, packaging, automotive, aerospace, and electronics to food and beverage, consumer goods, medical component manufacturing, robotics, semiconductors, and agriculture. In effect, machine vision technology is a sound investment for companies and a sure way to improve their productivity, quality control, and smart manufacturing capabilities.

For more information on how machine vision technology applications may benefit your company, contact EAM, Inc., trusted leaders in custom automated manufacturing machinery and industrial-engineered automation systems and solutions.