The Terminator movie franchise brought the concept of machine vision to the big screen like no other film before it, showing how machines might view the world. Although the movies were from the viewpoints of autonomous military robots, the machine antagonists – and protagonists, depending on the film – also imagined aspects of machine vision that today’s artificial intelligence (AI) can now achieve.

Real World Automation: Engineering Machines That See

As the brain processes all the things that human eyes see, a machine’s sight begins with a computer. Using video cameras as eyes, the computer converts the resulting visual data via analog to digital conversion (ADC) or digital signal processing (DSP). Just like organic eyes, machine vision can have varying sensitivity and resolution, allowing sight in dim light or to differentiate between objects. These two aspects of vision are symbiotic, with increasing sensitivity reducing resolution while decreasing sensitivity improves it.

There are many benefits to machine vision technology that make it superior to human sight. While human eyes see electromagnetic wavelengths from 390-770 nanometers, some video cameras can see a much wider range, with some having capabilities to see wavelengths in infrared, ultraviolet and even X-ray. Even binocular vision has been achieved in machines, which simply requires a greater amount of random-access memory (RAM), a more advanced processer, high-resolution cameras and an AI programmed to give it depth perception.

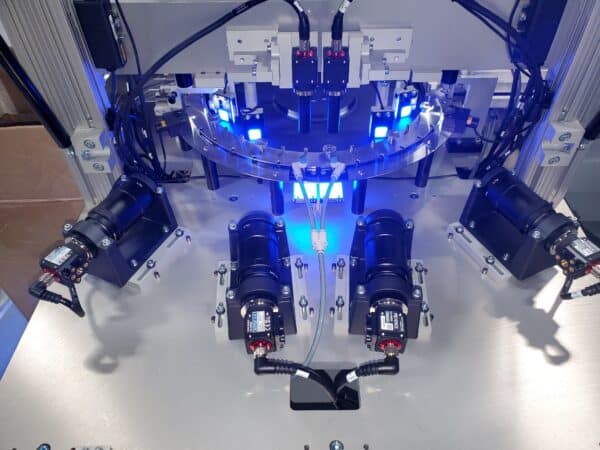

GIGI & Custom Automation for Sight

Most machine vision used for practical purposes outside of movies happens in factories. Manufacturing automation applications for machine vision require certain skills. One primary ability is simple pattern recognition, which allows a machine to rapidly and accurately find a component along a production line. These actions must also be repeatable. Machine vision can be categorized into four elements, represented by the acronym GIGI.

Guidance

Guidance involves locating a part, identifying its orientation, comparing tolerances and angling it correctly. Machine vision allows a robot to be more accurate and quicker than a human worker.

This enables robots to:

- Find and align components for assembly.

- Geometric pattern matching to pick up variations in lighting, contrast, scale, position and other patterns.

- Locating key features on components to enable precise positioning by aligning other machine vision tools.

- Package parts from conveyor belts.

- Pick components from or put them onto pallets.

- Put parts onto shelves.

- Remove components from bins.

These guidance techniques allow more versatile manufacturing automation, allowing companies to produce multiple products on the same production line and reducing the hardware required for inspection.

Identification

Machine vision can identify and recognize items in much the same way as scanners in stores read barcodes and other patterns based on shape, size or color. Using automation, manufacturing techniques can use machine vision to help prevent errors, monitor and adjust production, resolve production problems like bottlenecks and enable effective strategies to isolate issues regarding assembly.

This ability to trace products allows better:

- Asset tracking.

- Technical support.

- Tracking of warranty repair service.

- Verification of component authenticity.

Unlike conventional barcodes used in retail, production lines require codes that store a greater amount of information, such as unique serial numbers, lot numbers, product numbers and manufacturer.

Gauging

In order for a robot to act upon an object along an assembly line, it must be able to calculate distances and gauge the location of an object in space. When it comes to this sort of automation, engineering vision systems to see when measurements are incorrect allows a robot to ensure parts meet specifications.

Inspection

A key element that machine vision can fulfill lies in quality assurance of components during manufacturing. Automation helps identify irregularity and defects in parts that affect its function, along with other flaws that may occur during fabrication. Machine vision can inspect to:

- Automatically identify and classify potential defects based on geometry, contrast and texture through the use of statistical analysis.

- Calculate the number of items in a product, such as the number of cans in a case, pills in a bottle or pieces in a kit.

- Detect when machining operations do not meet specifications.

- Determine positioning of objects for labeling.

- Distinguish when products are contaminated.

- Ensure products are correctly packaged, with safety caps, seals and rings on containers are securely placed.

- Identify products with flaws, including bent needles, incomplete soldering or surface scratching.

- Measure infinitesimally small lengths, such as gaps on spark plugs.

- Note when features of specific products are incomplete.

- Sorting products once they have been identified, located and obtained.

- Verify quality standards for products.

To support machine vision systems, software applications utilize machine vision to conduct many different types of inspections, including libraries containing images of parts to show how they should appear.

Other Applications of Machine Vision

Applications for machine vision also include:

- Allows vehicles to operate without drivers by identifying objects and interpreting situations in order to make decisions by utilizing algorithms that detect and classify objects.

- By applying machine learning algorithms to medical images, doctors can detect, classify and partition images in order to perform tasks like identifying tumors, monitoring patient health and fitness, diagnosing diseases and more.

- Distinguishing characters through patterns of lightness and darkness in order to identify letters and numbers by font so as to make scanned documents editable.

- Recognizing faces has pushed the envelope of vision automation, engineering software that uses the geometric relationship of specific features and their patterns to identify people visually.

- Verifying signatures and handwriting by tracking not only the appearance of the handwriting upon an image plane and comparing it to other machine vision examples, but also examining how the signature or handwriting is generated.

An array of different uses likely will continue to improve current visual automation. Engineering machine vision to ensure currency authenticity is already being used by the US Bureau of Engraving and Printing. They currently use machine vision to inspect security features like watermarks and fluorescent threads when producing new $20, $50 and $100 bills.