The importance of custom machine vision as a component of modern industrial automation cannot be denied. When it comes to automation, engineering cameras, sensors and software into an automated factory will essentially provide it with sight that in many ways surpasses that of human sight. By using machine vision techniques, automated production lines can accurately understand images, allowing robots and other automated implements to participate in a wide array of tasks without human supervision.

Embracing Custom Automation: Engineering Machine Vision for Industry

As a tool used extensively to support industrial automation, engineering machine vision technology into smart factories enables manufacturers to better understand their operations. While related to computer vision, which specifically looks at identifying visual defects, machine vision entails the entire system that not only detects fabrication issues but also resolves these automatically, removing defective products from the production lines.

Benefits of utilizing machine vision for manufacturing automation include:

- Allowing greater flexibility during production, especially regarding guidance of robots, verifying prior operations, measurements and gauging.

- Decreasing costs of production through automating quality control and allowing detection of flaws earlier in the manufacturing process.

- Diminishing the floor space needed by replacing human operators with vision systems.

- Helping control inventory through recognizing, identifying and labeling products

- Improving quality by augmenting inspection, gauging and measurements while also verifying assembly operations

- Increasing productivity by enabling the automation of repetitive tasks once done manually.

- Lessening scrap production in industrial applications through more accurate measurements, gauging and inspections.

- Lowering capital investment by improving equipment performance to delay obsolescence.

- Offering tighter process controls by that provide a more complete view of manual processes through gathering and analysis of data gathered and analyzed.

- Reducing downtime and setup time by allowing changeovers to be programmed in advance.

Machine vision technology offers a wide array of benefits to modern industry. The basic elements of which are summed up by the acronym GIGI (guidance, identification, gauging and inspection). All these aspects of machine vision technology are used for various purposes within smart manufacturing. Automation relies on a smart factory’s ability to react to challenges that crop up during production, and machine vision plays a vital role in this process.

Five key machine vision applications support manufacturing automation:

Reading Barcodes

Essentially acting in much the same way as retail barcode scanners, machine vision technology accurately and quickly controls storage and distribution tasks during and after production. It’s one of the most widely-used aspects of machine vision, a role that’s integral to modern logistics. Machine vision techniques allow for the automatic identification of objects while also collecting and storing data concerning them into computerized systems. These aren’t just related to barcodes, but also relates to quick response (QR) codes and radio frequency identification (RFID) tags.

Detecting Defects

Automation engineering that utilizes machine vision technology to detect product defects helps improve the quality of manufactured goods, by programming AI software to identify defects along the production line and instructing the system to remove them. Through the use of machine learning algorithms, automated production lines with machine vision capabilities greatly reduce the chance of human error during quality inspections. Visual data can also assist in predictive maintenance of manufacturing equipment, especially when used in conjunction with sensors that can detect variations in heat and vibrations.

Matching Patterns

Machine vision software enables pattern matching that allows automated systems to find objects or features relevant to production. Without such software, robots and other automated machinery aren’t able to count, identify, inspect, locate or measure a part, much less guide it into position. This aspect of machine vision is one of the most challenging, as it mimics how human brains register what they see. This requires machine learning algorithms that enable systems to recognize components based on their patterns, but which need to allow for a certain amount of variability between parts. This requires AI software that can effectively and quickly analyze patterns of objects as they move along the production line, and which enable appropriate actions to ensure accuracy and reliability, along with making this process repeatable.

Sorting

Human vision is limited when it comes to detecting various color shades or determining slight variations in dimension. For example, color-based part identification can sort components based on how they’re colored, with an automated robotic arm functioning in conjunction with machine vision systems to conduct pick and place operations. Image processing systems then sort with the assistance of programmable motors within the system. Such custom automation visual systems have become integral tools used in the automotive, agricultural and pharmaceutical industries.

Detecting Absence or Presence

In some cases, machine vision systems look for specific objects within their field of vision to detect which items need to be focused upon for inspection or other purposes. This allows the system to focus only on relevant objects. Detecting the absence or presence of specific objects is used in sorting, controlling quality, managing inventory and for other applications where it’s necessary to confirm the absence or presence of a specific component or object in the image.

Machine Vision: Other Automation Engineering Applications

The AI within machine vision technology also makes it useful in other aspects of manufacturing. Automation improves safety in industrial settings, while also greatly contributing to efficient factory operations. With advancements in AI and deep machine learning technology, manufacturing automation will continue to integrate sensing and monitoring devices with custom automation software to allow it to do even more. In addition to the above, machine vision is useful for the following:

- Counting parts manually is both slow and tedious, and human operators are prone to mistakes when counting. This can cause production delays, so utilizing machine vision for identifying algorithms and detecting parts will enable greater efficiency with less error.

- Guiding robots and other manufacturing automation equipment allows the proper placement and positioning of a component once identified. It allows automated systems to repeat tasks with accuracy and extraordinary precision in environments unsafe for human operators.

- Locating the position or coordinates of an object, which assists in the management of supply chains and helps find misplaced objects more quickly and easily. Machine vision paired with AI keeps track of components throughout the production process.

- Measuring the length, surface area, width and volume of various components and other objects used throughout production allows manufacturers to determine the amount of space necessary for shipping. Physical inspection only estimates, whereas machine vision with AI capabilities allows precise calculations of an object’s geometrical dimensions based on an image.

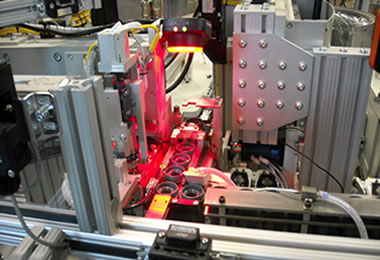

Custom Automation Machine Vision by EAM

EAM Inc. provides advanced custom automation technology with its EAMVision custom automation technology. Utilizing cutting-edge technologies that include artificial intelligence software with deep learning capabilities, EAMVision offers solutions to some of the most challenging industrial applications. By integrating turnkey industrial automation with machine vision, we offer solutions across a wide array of industries.

EAMVision works in the following sectors, with properties that assist with:

- Automotive: positioning and alignment of components, as well as sorting material, guiding robots and inspecting torque convertors.

- Electronic: inspecting battery surfaces, coatings, coplanarities and solders.

- Food & Beverage: inspecting bottles, labels and seals, along with verifying bottle types.

- Manufacturing: providing three-dimensional, barcode and surface inspections, along with barcode reading and precision measurements.

- Pharmaceutical: ensuring safety integrity of packaging and safety seals, along with validating codes and inspecting for contamination.

- Semiconductors: inspecting macro and micro wafers, reticles and pellicles, front and back ends and water edge.

Founded on the need to improve factories that utilize automated technology, our EAMVision fills the gap between the needs of industry with the ongoing research and development of machine vision technology. With a fundamental understanding about how machine vision that learns impacts industry, our automation engineering continues to create innovative solutions for challenging manufacturing problems.